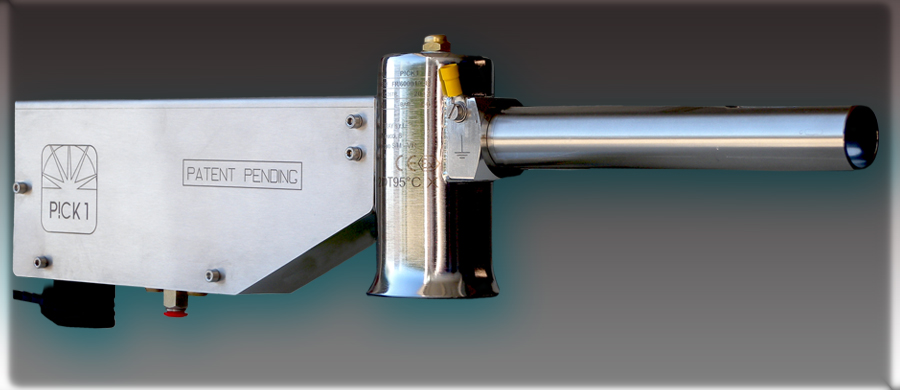

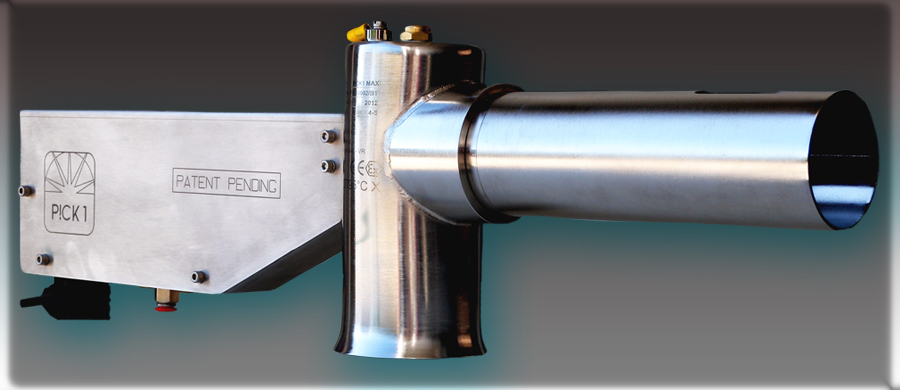

Freeray created P!CK 1®, the automatic sampling device of flowing solid materials.

P!CK 1®is the solution to the well-known problem of getting "representative sample” of a moving mass which, by its bulky nature, not always perfectly uniform and often loaded with patchy distributed pollutants, requires the collection of "elementary samples" in large numbers and in different places. An accurate and representative sampling is essential in order to have reliable results in the quality control of raw materials or finished products.

Our device allows to carry out, automatically, a dynamic sampling of representative samples of solid materials in powder, grains or granules. The sampling cycle is fully automated and occurs in flux, during transit. It can be taken continuously, with variable and programmable frequency, a predetermined number of micro-units which make up the aggregate representative sample of the batch produced.

P!CK 1®

It’s a compact and robust unit, easy to dismantle and resistant to environmental agents. It can be easily installed in any industrial plant and integrates perfectly in each productive or storage system (where there are mechanical systems of internal transport).

Sampling Reliability

The complete operating flexibility of the sampling parameters gives the quality control manager the possibility to carry out his activity without running the risk that the batch sample is not representative of the lot therefore defeating any analytical result.

Easy

Our device quickly becomes friend of the operators who can use it easily and intuitively, forgetting the old samplers, that involve physical efforts, have difficulty in accuracy and are often sources of anomalous dusts.

Autonomous

P!CK 1 can operate in a perfect autonomy (controlled by its own control panel which, in the various available versions, only requires electricity and compressed air), but it can also be integrated to any automation, such as additional device.

Workflow Quality

P!CK 1 while performing its primary function (control of incoming raw materials, quality control of inner production, guarantee to customers the quality of the product on sale, etc...) allows (in the most complete version, equipped with "touch screen" control panel) to record a series of events useful for the traceability of the processes and for verifying the efficiency of production plants.